Wat is zeefdruk?

Wil je jouw logo op glaswerk of servies laten bedrukken? Dit kan op verschillende manieren, waaronder zeefdruk. Wat is zeefdruk precies? Welke drukmogelijkheden zijn er nog meer? En welke drukmogelijkheid raden wij jou aan? Je leest het in deze blog! Wij helpen je graag in deze zoektocht.

De naam zegt het al: jouw glaswerk of servies wordt bedrukt met behulp van een zeef. We maken een sjabloon van jouw ontwerp, waarbij alleen het gedeelte van de zeef waar het ontwerp zit open is. De rest is afgedekt. Vervolgens wordt inkt door deze open delen gedrukt, waardoor jouw logo of afbeelding op het glas of servies komt. Daarna wordt het bedrukt materiaal gedroogd, zodat de inkt goed blijft zitten en het product klaar is voor gebruik! Hieronder wordt in vier stappen uitgebreider uitgelegd wat het drukproces is van zeefdruk.

- Het designproces. Jij als klant wil graag jouw logo op glazen bedrukken of servies bedrukken. Mooi! Dat kan. Jij bepaalt welk logo er bedrukt wordt, wij maken de proefdruk voor je en jij geeft akkoord op de proefdruk die we maken. Zo heb jij de lead over wat er bedrukt wordt en bepaal jij het eindresultaat!

- Voorbereiden van het sjabloon. Na jouw akkoord op de proefdruk en de offerte starten wij het orderproces. Allereerst beginnen we met de voorbereiding van het sjabloon. We maken een sjabloon op basis van jouw logo of ontwerp. Er wordt een emulsie aangebracht over de hele zeef. Vervolgens wordt jouw ontwerp (logo) met een negatieffilm op de zeef gelegd en belicht met Uv-licht. Hierdoor worden de delen van de zeef die bedekt zijn door jouw ontwerp uitgespoeld, waardoor de inkt alleen op de juiste plekken door de zeef heen kan. Zo kan de inkt alleen door jouw ontwerp heen en wordt het juiste logo bedrukt.

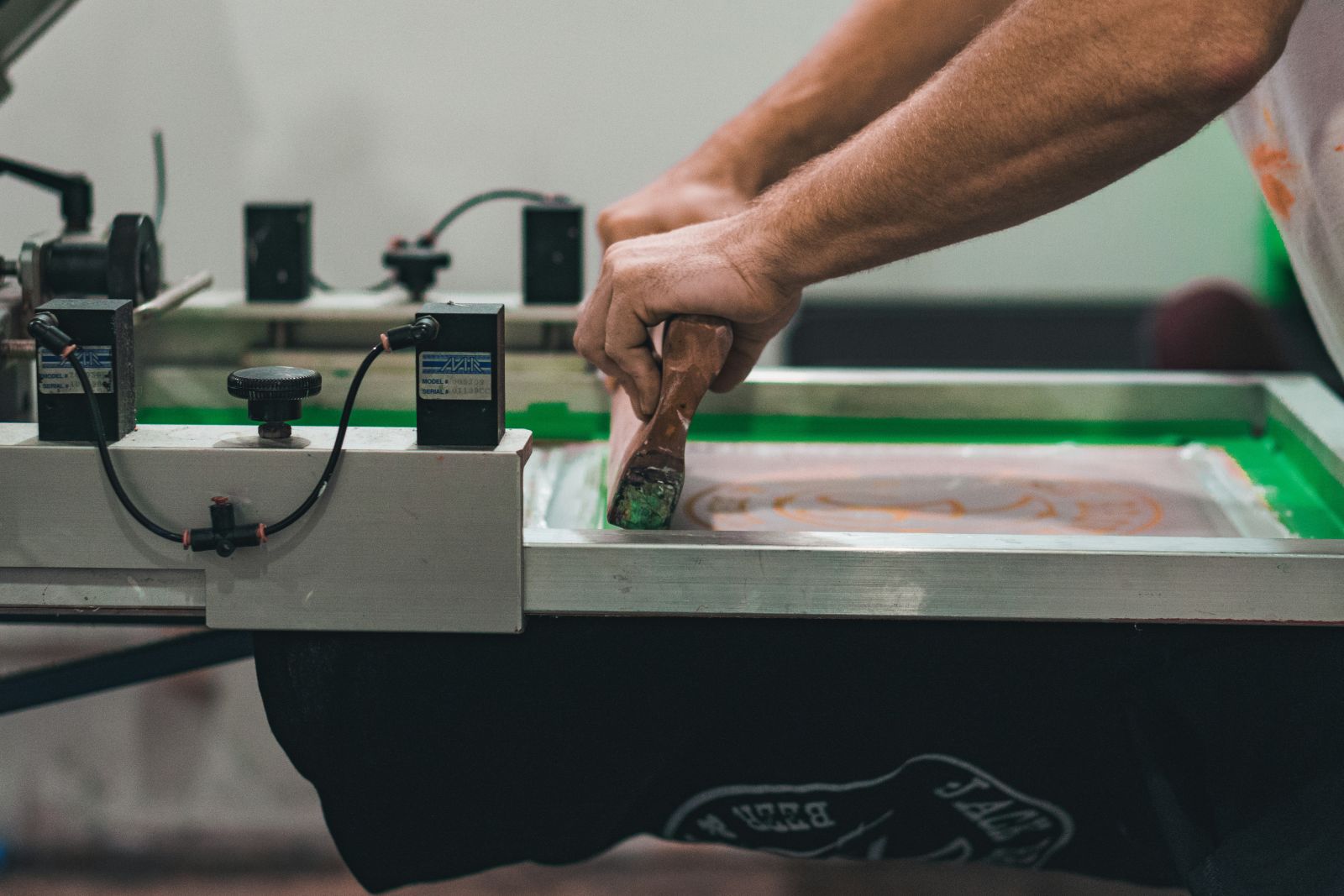

- Aanbrengen van de inkt. Wanneer het sjabloon klaar is, wordt het op de zeefdrukmachine geplaatst. De inkt wordt boven op de zeef aangebracht en vervolgens met een soort rubberen trekker over de zeef verspreid. Hierdoor wordt de inkt door de open delen van het sjabloon op het glaswerk gedrukt. Bij ontwerpen met meerdere kleuren wordt voor elke kleur een aparte zeef en druklaag gebruikt. Dit zorgt voor een gedetailleerd en kleurrijk eindresultaat.

- Droogproces en afwerking. Na het aanbrengen van de inkt moet het bedrukte glaswerk drogen. Dit kan op verschillende manieren, bijvoorbeeld in een oven. Dit proces zorgt ervoor dat de inkt in het glas komt, waardoor het logo krasbestendig is en lang meegaat.

Voordelen en nadelen van zeefdruk

Zeefdruk kent een aantal voor- en nadelen.

Voordelen

- Bedrukking door middel van zeefdruk is duurzaam. Het gaat lang mee, tot wel 500 wasbeurten!

- Zeefdruk is mogelijk in veel felle en veel verschillende kleuren.

- Het drukproces is machinaal en daarmee exacter dan mensenwerk.

Nadelen

- Relatief hoge opstartkosten.

- Bedrukken in een lage oplage alleen mogelijk in één kleur.

Zeefdruk in vergelijking met andere druktechnieken

Naast zeefdruk zijn er nog andere technieken om glaswerk en servies te bedrukken:

- Transferdruk: Er worden stickers gemaakt, geknipt en geplakt. Daarna gaat het glaswerk of servies met de stickers erop de oven in en wordt het logo op het product gebakken. Dit proces handig als jouw logo meerdere kleuren bevat en veel details bevat.

- Digitale print: Digitale druk is goed voor ontwerpen met veel kleuren en veel details. Een andere term hiervoor is bedrukking in Full Colour. Deze techniek maakt gebruik van digitale printers die direct op het materiaal printen, perfect voor kleinere oplages of gepersonaliseerde items.

- Graveren: Een permanente methode waarbij het ontwerp in het glas of servies wordt gegraveerd. Hierbij wordt er een heel dun laagje uit het glaswerk gelasergraveerd. Dit geeft een luxe uitstraling en is ideaal voor speciale gelegenheden of als cadeau.

Welke druktechniek is geschikt voor jou?

De keuze voor een druktechniek hangt af van een aantal dingen: de door jou gewenste oplage, het ontwerp en het materiaal. Wij raden zeefdruk aan als je op zoek bent naar een duurzame en kleurrijke bedrukking die lang meegaat en goed bestand is tegen slijtage. Heb je een moeilijk ontwerp met veel kleuren of wil je gepersonaliseerde ontwerpen in kleine oplage? Dan is digitale print een betere optie. Voor luxe, subtiele afwerkingen kun je het beste kiezen voor graveren.

Wil je meer weten over de mogelijkheden? Neem contact met ons op! We helpen je graag bij het maken van de beste keuze voor jouw gepersonaliseerde glaswerk en servies. Vraag vrijblijvend een offerte of een digitale proefdruk aan!

Inhoudsopgave

Populaire blogs