Welke verschillende druktechnieken zijn er?

Welke druktechniek past het beste bij jou? Servies of glazen bedrukken is een geweldige manier om je merk, boodschap of ontwerp echt op te laten vallen. Er zijn veel verschillende drukmogelijkheden: van fijne gravures tot kleurrijke prints, en allemaal hebben ze hun eigen karakter. Maar hoe kies je de juiste methode? In deze blog nemen we je mee door de verschillende soorten druktechnieken. Zo ontdek je welke techniek het beste bij jouw wensen past en hoe je iets creëert dat écht indruk maakt. We vertellen het je graag!

Wat is bedrukken en waarom zou je het doen?

Wat is bedrukken?

Wat is bedrukken nou precies? Het lijkt een hele simpele vraag, maar dat kan nog best uitdagend zijn. Bedrukken is eenvoudig gezegd het aanbrengen van een logo op een voorwerp. Het bedrukken van glaswerk of servies kan op heel veel verschillende manieren gebeuren. We leggen verder in deze blog per drukmogelijkheid uit hoe het exact in z’n werk gaat.

Waarom bedrukken?

Waarom zou jij bijvoorbeeld je logo laten bedrukken op mokken? In een andere blog legden we je uit waarom het bedrukken van jouw logo op servies of glaswerk de beste vorm van sluikreclame is.

Allereerst zorgt het bedrukken van onder andere glazen of mokken ervoor dat jouw merk/branding completer is. Als gasten in jouw horecazaak of sollicitanten van jouw onderneming bijvoorbeeld zien dat jij mooi bedrukt servies hebt, nemen ze jou serieuzer en leg je ze in de watten. Dit komt doordat jij de mensen bedient met mooie producten.

Daarnaast kan je je gasten/bezoekers gebruiken als marketeers. Als zij op social media een foto posten waarin jouw logo te zien is, maken ze gratis reclame voor je. Dat is ideaal voor jouw (horeca)onderneming!

Verder zorgt het bedrukken van servies of glaswerk ervoor dat je met het bedrukken van je logo een grotere naamsbekendheid opbouwt. Als je een naam zeven keer ziet of hoort, blijf je het onthouden. Dit wordt ook wel ‘The Rule of 7’ genoemd. Als mensen het logo van jouw bedrijf opmerken, blijven ze het dus onthouden. Ideaal!

Welke druktechnieken zijn er?

Er zijn veel verschillende manieren om mokken, borden, glazen en nog veel meer producten te voorzien van jouw logo. Transferdruk, zeefdruk, graveren, bedrukken met graveerlook, digitale druk en sublimatiedruk: allerlei druktechnieken om producten te voorzien van jouw logo. We leggen in het kort alle druktechnieken uit, zodat jij kan bedenken welke druktechniek het beste bij jouw verwachtingen/wensen past!

Transferdruk

Hoe werkt transferdruk?

Transferdruk is de meestgebruikte druktechniek. Zodra jij bepaald hebt welk logo of welke tekst jij graag zou willen laten bedrukken op bijvoorbeeld een mok, gaat het drukproces van start. Allereerst worden de transfers geprint. Transfers lijken op stickers: jouw logo wordt geprint in inkt, zodat het later gebakken kan worden op het product.

Zodra de transfers zijn geprint, worden ze gecheckt: lijkt het geprinte design op jouw gewenste resultaat? Dan gaan we aan het werk. De transfers worden op het product geplakt en dan is het tijd voor de oven. De producten worden gebakken: bij het bedrukken van glaswerk bereikt de oven een temperatuur van 600 graden en bij het bedrukken van servies zelfs 800 graden Celsius.

In de oven smelt de beschermlaag die bovenop de inkt zat en blijft alleen het logo over. Het logo wordt in het product gebakken, zodat het goed blijft zitten. Nadat de bedrukte mokken, glazen of andere producten uit de oven zijn gehaald, worden ze afgekoeld en gecheckt. Na het volledige productieproces worden de producten ingepakt en verzonden!

Voordelen en nadelen van transferdruk

De voordelen zijn talrijk:

- Transferdruk is ideaal voor logo’s met meerdere kleuren. Het is mogelijk om tot wel 7 kleuren te bedrukken!

- Het bedrukken van jouw logo aan de hand van transferdruk is 100% krasvast en vaatwasmachinebestendig.

- Als jouw logo veel (of weinig) details bevat, is transferdruk een goede druktechniek. Zolang jij een vectorbestand aanlevert voordat wij een digitale proefdruk maken, is alles mogelijk!

- Transferdruk is bij kleine oplages al mogelijk. Dit komt door de lage opstartkosten. Opstartkosten zijn de kosten voor het instelwerk. Denk dan aan het maken van de transfers, wat tijd en geld kost.

Er is één nadeel:

- Doordat transferdruk zulke mooie ambacht is, kan er soms een foutje gemaakt worden bij het plakken. Het logo kan dan een beetje scheef op het product terechtkomen. Dit gebeurt echter zelden.

Zeefdruk

Hoe werkt zeefdruk?

Allereerst wordt het design bepaald. Weet jij welk logo je wilt laten bedrukken en heb je akkoord gegeven op de door ons gestuurde digitale proefdruk? Mooi zo! Dan gaan we aan de slag met het drukproces. De eerste stap in dit drukproces is het voorbereiden van het sjabloon.

Hoe wordt het sjabloon voorbereid? Over de gehele zeef wordt een emulsie aangebracht. Vervolgens wordt het door jou gewenste ontwerp door middel van een transparant vel op de zeef gelegd en wordt het met behulp van Uv-licht belicht. Dit zorgt ervoor dat het gedeelte van jouw ontwerp weggespoeld wordt, zodat de inkt alleen uit het gedeelte van de zeef kan komen waar jou ontwerp staat.

Het sjabloon wordt op de zeefdrukmachine geplaatst, waarna de inkt bovenop de zeef wordt aangebracht. Met een rubberen trekker wordt de inkt over de zeef verspreid. Hierdoor komt de inkt door de open delen van het sjabloon op het product terecht. Voor ontwerpen met meerdere kleuren wordt voor elke kleur een aparte zeef gebruikt. Dit zorgt voor een kleurrijk en gedetailleerd resultaat. Meer weten over zeefdruk? Lees de blog!

Voordelen en nadelen van zeefdruk

Zeefdruk kent een aantal voordelen, namelijk:

- Je glaswerk of servies laten bedrukken door middel van zeefdruk is erg duurzaam. Het logo gaat wel meer dan 500 wasbeurten mee!

- Zeefdruk is in veel kleuren mogelijk.

- Het drukproces wordt door een ronddrukmachine uitgevoerd, waardoor dat preciezer gaat dan door mensen handen.

Verder zijn er ook een aantal nadelen:

- De opstartkosten zijn door het maken van onder andere het zeefraam relatief hoog.

- Het bedrukken van een kleine oplage is alleen mogelijk in één kleur.

Graveren

Hoe werkt graveren?

Graveren is mogelijk op glas. Zodra het design en de digitale proefdruk door jou zijn goedgekeurd gaan we aan de slag met het graveren van de glazen. Het drukbestand wordt digitaal geüpload naar de graveermachine. Nu kan de machine aan de slag!

Hoe gaat een graveermachine te werk? Allereerst moet het glas in de machine geplaatst worden. Dan wordt er een laagje van de buitenste rand van het glas eruit gegraveerd. Dit gebeurt aan de hand van een lasergravure die ervoor zorgt dat het logo in het glas terechtkomt. Dit resulteert in een mooie luxe uitstraling: het logo voelt een beetje ruw aan en heeft een grijs-witte kleur.

Nadat alle producten gegraveerd zijn, worden ze goed ingepakt en zijn ze klaar om verzonden te worden. Binnen 5-10 werkdagen kan jij genieten van je mooi gegraveerde producten!

Voordelen en nadelen van graveren

Welke voordelen heeft graveren?

- De glazen zijn erg duurzaam en vaatwasmachinebestendig: een gravure gaat voor altijd mee en kan niet verdwijnen/vervagen.

- Graveren zorgt voor een elegante en luxe uitstraling.

- De levertijd bij graveren is erg kort: 5-10 werkdagen.

En de nadelen van graveren?

- Graveren is altijd in één kleur, namelijk lichtgrijs. Het is dus niet mogelijk om meerdere kleuren te laten graveren.

- Graveren is niet mogelijk op servies, met uitzondering van een aantal mokken.

Mokken graveren

Sinds kort is het ook mogelijk om een aantal mokken te graveren. In feite is het drukproces hetzelfde als bij het graveren van glazen. De mok dient een gekleurde (en dus niet witte) buitenzijde te hebben. De lak van de mok wordt eraf gegraveerd, waardoor het logo in het wit zichtbaar is op de gekleurde mok. Mooi hé?

Bedrukken met graveerlook

Hoe werkt bedrukken met graveerlook?

Het is eigenlijk heel simpel. Bedrukken met graveerlook zorgt ervoor dat het glaswerk eruitziet alsof het een gravure heeft, maar neemt de voordelen van bedrukken mee! Het wordt ook wel imitatie-ets genoemd. Het logo dat door jou opgestuurd is bedrukken wij op de glazen. Daarna volgen dezelfde stappen als bij transferdruk. Het enige wat anders is, is dat de graveerlook ook alleen bedrukt kan worden in grijs.

Dit resulteert in mooie glazen. Het logo is in het grijs bedrukt op het glas. Zo ziet het eruit als een gravure, maar is het in feite een gewone transferdruk.

Voordelen en nadelen van bedrukken met graveerlook

Er zijn een aantal voordelen ten opzichte van normaal graveren:

- Het logo is beter zichtbaar bij bedrukken met graveerlook dan bij ‘normaal’ graveren. Dit komt door de condens die over de normale gravure heen kan gaan.

- Bij bedrukken met graveerlook heb je een aantal opties die je bij normaal graveren niet hebt. Allereerst kan bij de graveerlook het logo groter bedrukt worden. Daarnaast kan het logo ook rondom het glas bedrukt worden. Dit kan bij graveren niet.

Welke nadelen brengt bedrukken met graveerlook met zich mee?

- Bedrukken met graveerlook heeft niet dezelfde luxe uitstraling als een echte gravure.

- De bedrukking is minder duurzaam en kan na veel gebruik slijten, terwijl een gravure permanent in het glas zit.

Digitale druk

Hoe werkt digitale druk?

Digitale druk is een innovatieve druktechniek. Hoe werkt het eigenlijk? Alles begint met het design. Zodra jij akkoord hebt gegeven op de proefdruk die je per e-mail ontvangt, kunnen we aan de slag! Het logo wordt geüpload naar onze digitale printer. Dit zorgt ervoor dat de printer exact weet welk ontwerp op jouw product moet komen.

Het grootste voordeel van digitale druk is dat je álle kleuren kan bedrukken. De bedrukking is dus ‘Full Color’ en dus ideaal als jij een ontwerp hebt wat bestaat uit veel kleuren.

Nu is het tijd voor het drukproces. Het product wordt in de printer geplaatst, en hier begint de magie. Het product draait razendsnel rond, terwijl de inkt van boven naar beneden wordt aangebracht. Dit gebeurt in verschillende rondes.

In de eerste drukronde worden de witte gedeeltes van het design bedrukt op het product. Daarna worden alle gekleurde gedeeltes bedrukt. Als laatste wordt er een beschermende en krasvaste laklaag bovenop de bedrukking bedrukt. Zo gaat de bedrukking langer mee!

Voordelen en nadelen van digitale druk

Allereerst de voordelen. Wat is er zo fijn aan digitale druk?

- Het werd al even eerder benoemd, maar de bedrukking is bij digitale druk ‘full color’. Dit betekent dat álle kleuren bedrukt kunnen worden, waardoor de mogelijkheden eindeloos zijn.

- Doordat de opstartkosten laag zijn, is het mogelijk om kleine oplages af te nemen als je je producten laat bedrukken met behulp van digitale druk.

- Weinig kans op fouten. Doordat een machine verantwoordelijk is voor het bedrukken van de producten, is er weinig kans op fouten. De digitale printer print enorm nauwkeurig en maakt dus weinig fouten.

Wat zijn de nadelen?

- Digitale druk kan tijdrovend zijn. Doordat ieder product stuk voor stuk bedrukt wordt, duurt het relatief lang om grote oplages te bedrukken.

- Een ander nadeel is de vaatwasmachinebestendigheid. De digitale druk is op de producten niet 100% vaatwasmachinebestendig. De producten zijn bij digitale druk ongeveer 300 wasbeurten vaatwasmachinebestendig. Hoewel veel producten hun logo heel lang behouden, ook als ze in de vaatwasser zijn geweest, kunnen we niet 100% garanderen dat het logo vaatwasmachinebestendig is.

Sublimatiedruk

Hoe werkt sublimatiedruk?

Zodra jij een design of een logo opstuurt, wordt er voor jou een digitale proefdruk gemaakt. Vind jij die perfect en keur je hem goed? Mooi zo! Dan gaan we voor je aan de slag en start het drukproces. Zou je willen weten wat jij kan doen voor een goed design? Lees het dan in deze blog.

Allereerst: wat is sublimatiedruk? Sublimatiedruk is een druktechniek waarbij het mogelijk is om rondom een mok een foto te laten bedrukken. Wil jij een foto laten bedrukken op mokken? Dan is dit ideaal! De foto wordt uitgeprint op transferpapier. De volgende stap is het uitknippen van de transfers en het plakken van de transfers op mokken.

Als de transferstickers op de mok zitten, gaat er een siliconen band om de mok en het papier heen. Deze is hittebestendig en zorgt ervoor dat de transfer perfect op de mok blijft zitten. Nu is het tijd voor het bakken in de oven. Er kunnen grote getale aan mokken de oven in. De oven bereikt een temperatuur van 200 graden Celsius en de mokken bakken 20-30 minuten, zodat de afbeelding goed in de mok blijft zitten.

Als de mokken uit de oven komen, moeten ze even afkoelen. Daarna gaan de siliconen band en het papier van de mok af. Het enige wat dan nog overblijft is een mok met een mooie afbeelding!

Voordelen en nadelen van sublimatiedruk

Er zijn een aantal voordelen van sublimatiedruk.

- Het is bij sublimatiedruk mogelijk om volledige afbeeldingen te laten bedrukken. De bedrukking is erg gedetailleerd en dus prachtig!

- Bij sublimatiedruk zijn alle kleuren mogelijk. Ook sublimatiedruk is net als digitale druk full color. Alles is mogelijk!

Nadelen:

- Sublimatiedruk is niet 100% vaatwasmachinebestendig.

- Sublimatiedruk is niet 100% krasvast.

Dus: welke druktechniek is voor jou?

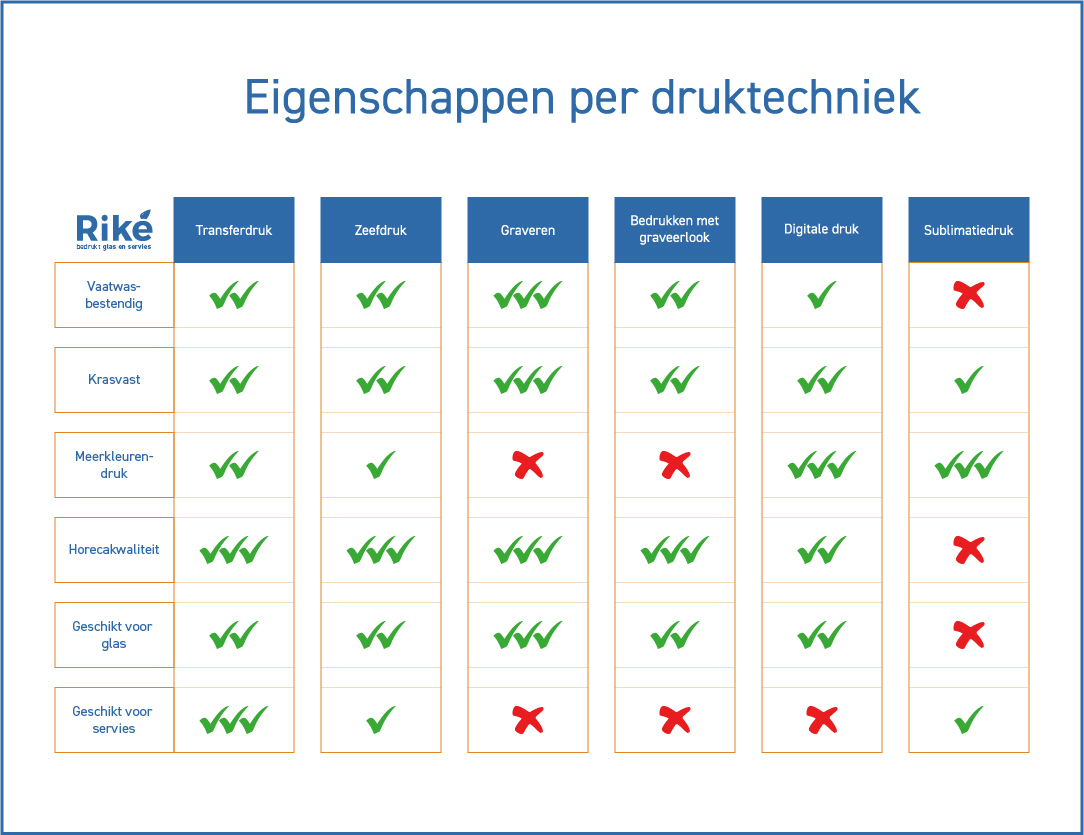

Welke druktechniek past nou het beste bij jou? Dat ligt natuurlijk aan hoe jouw design eruitziet en wat jouw wensen zijn. Heb je een logo met één tot drie kleuren? Dan raden we aan om ‘gewoon’ voor transferdruk of zeefdruk te gaan. Heb je een afbeelding die je wilt bedrukken? Dit kan op veel mokken en borden. Wil je mooie glazen met een luxe uitstraling? Dan is graveren ideaal. Alles is mogelijk! Bekijk in de infographic hieronder welke eigenschappen de verschillende drukmogelijkheden wel of niet hebben.

Vraag maar raak

Heb je vragen over welke druktechnieken wij aanraden? Stel gerust je vraag! Wij staan voor je klaar. We maken graag een offerte en een gratis digitale proefdruk voor je. Deze kan je binnen één werkdag verwachten. Vraag dus gerust een offerte aan. Ben je er al over uit? Bestel dan meteen gemakkelijk via onze webshop. Samen komen we tot een mooi resultaat.

Inhoudsopgave

Populaire blogs

.jpeg)